The Mitsubishi Factory in Pasig is a cornerstone of industrial progress in the Philippines, representing Mitsubishi Motors Corporation’s dedication to innovation, sustainability, and economic development. Strategically located in Pasig City, one of Metro Manila’s busiest business hubs, this factory has established itself as a vital player in the country’s automotive industry. Over the years, it has become more than just a manufacturing facility; it is a symbol of reliability, excellence, and technological advancement.

This article delves deeply into the Mitsubishi Factory in Pasig, exploring its history, operations, sustainability initiatives, community impact, and the challenges it faces in an ever-changing industry. With a focus on innovation and economic contribution, this comprehensive overview underscores why the Mitsubishi Factory in Pasig remains a significant force in the Philippines’ industrial landscape.

A Historical Perspective

Mitsubishi Motors: A Legacy of Excellence

Mitsubishi Motors Corporation has a storied history that began in 1917 when it introduced Japan’s first mass-produced car, the Mitsubishi Model A. Over the decades, the company expanded its operations globally, becoming a leader in automobile manufacturing and technology. In the Philippines, Mitsubishi’s presence is a testament to the company’s commitment to bringing world-class automotive solutions to a growing market, much like the innovation and performance seen in the BMW F82 M4.

The Mitsubishi Factory in Pasig was established in the 1980s, a time when the Philippine economy was transitioning toward greater industrialization. Pasig City, known for its strategic location and proximity to Metro Manila’s major business districts, was an ideal choice for the factory. From its inception, the facility aimed to serve as a hub for local vehicle production while contributing to the broader Southeast Asian market, similar to the innovative developments seen in Cary Supercars 2025.

Growth Through the Decades

In its early years, the Mitsubishi Factory in Pasig focused on assembling vehicles for the local market, starting with models such as the Mitsubishi Lancer and Mitsubishi Galant. As demand grew, so did the factory’s capacity. Technological upgrades and process improvements allowed the facility to increase production volumes while maintaining Mitsubishi’s stringent quality standards.

By the 2000s, the factory had expanded its role to include the production of vehicle parts for export, cementing its importance in Mitsubishi’s global supply chain. This growth was accompanied by investments in workforce training, modern machinery, and sustainability initiatives, solidifying the factory’s position as a leader in the Philippine automotive industry.

Economic Contributions

A Major Employer

The Mitsubishi Factory in Pasig is a significant source of employment, providing jobs to thousands of Filipinos. From assembly line workers and engineers to administrative staff and logistics professionals, the factory supports a wide range of occupations. This employment impact extends beyond the factory itself, creating opportunities in related industries such as parts manufacturing, transportation, and retail.

By prioritizing local hiring and skill development, Mitsubishi not only contributes to the economic well-being of Pasig City but also empowers its workforce. Regular training programs ensure that employees are equipped with the latest technical knowledge, enabling them to meet international manufacturing standards.

Strengthening the Supply Chain

The factory’s operations rely on a network of local suppliers for raw materials, components, and services. This collaboration supports the growth of small and medium enterprises (SMEs), fostering a robust automotive supply chain in the Philippines. By sourcing locally, Mitsubishi reduces production costs and promotes sustainable economic development.

Contribution to GDP

As one of the largest automotive manufacturing facilities in the country, the Mitsubishi Factory in Pasig plays a crucial role in the Philippines’ gross domestic product (GDP). The factory’s output not only satisfies local demand but also reduces the need for imported vehicles, keeping economic value within the country.

Advanced Manufacturing Practices

Automation and Robotics

The Mitsubishi Factory in Pasig is at the forefront of advanced manufacturing. Automation and robotics are integral to its operations, ensuring precision and consistency in every vehicle produced. Robotic systems are used in various stages of production, including:

- Welding: Robotic arms perform precise welding operations, creating strong and durable vehicle frames.

- Painting: Automated painting systems ensure uniform coverage and high-quality finishes, while reducing paint waste.

- Assembly: Robots assist in the installation of complex components, improving efficiency and reducing assembly time.

These technologies not only enhance product quality but also optimize production efficiency, enabling the factory to meet high demand without compromising on standards.

Lean Manufacturing Principles

Mitsubishi has adopted lean manufacturing principles to maximize efficiency and minimize waste. This approach involves:

- Streamlining workflows to eliminate unnecessary steps.

- Reducing waste in materials, time, and energy.

- Continuously improving processes through feedback and innovation.

By implementing these principles, the factory achieves higher productivity and lower operational costs, ultimately benefiting consumers with competitively priced vehicles.

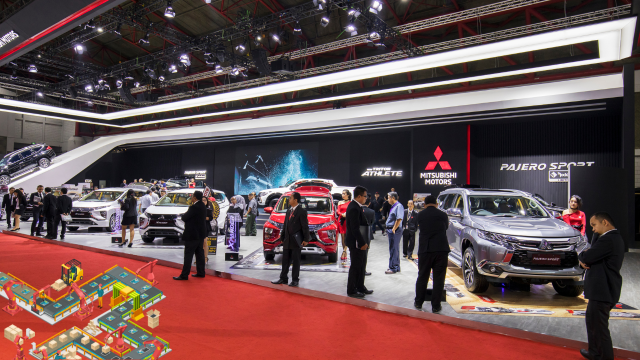

Products of the Mitsubishi Factory in Pasig

Locally Manufactured Vehicles

The Mitsubishi Factory in Pasig produces several key vehicle models that cater to the needs of Filipino consumers. Each model is designed to offer durability, efficiency, and reliability in diverse driving conditions.

- Mitsubishi Mirage

- A compact, fuel-efficient car that’s perfect for urban commuting.

- Known for its affordability and low maintenance costs, the Mirage is a popular choice among first-time car buyers.

- Mitsubishi L300

- A versatile light commercial vehicle widely used for businesses.

- With its spacious cargo area and robust design, the L300 is ideal for transporting goods in both urban and rural settings.

- Mitsubishi Montero Sport

- A luxurious SUV that seamlessly blends power, elegance, and comfort.

- Equipped with advanced safety features and a powerful engine, the Montero Sport is well-suited for families and off-road enthusiasts.

Export Contributions

In addition to producing vehicles for the domestic market, the Mitsubishi Factory in Pasig manufactures parts and components for export. These exports support Mitsubishi’s global supply chain, showcasing the technical expertise and high standards of Philippine manufacturing.

Sustainability Initiatives

Commitment to Environmental Responsibility

Mitsubishi Motors Corporation has a long-standing commitment to sustainability, and the Pasig factory exemplifies this ethos. The facility incorporates eco-friendly practices at every stage of production, minimizing its environmental footprint.

- Energy Efficiency

- The factory uses energy-efficient machinery and lighting systems to reduce electricity consumption.

- Automated systems optimize energy use in production processes, ensuring minimal waste.

- Waste Management

- An effective recycling program minimizes waste by repurposing materials like metal, plastic, and paper.

- Hazardous waste is disposed of responsibly, in compliance with environmental regulations.

- Water Conservation

- The factory employs water-saving technologies, such as closed-loop systems, to minimize water usage.

- Recycled water is used for non-potable purposes, such as cooling and cleaning.

Renewable Energy Integration

The Mitsubishi Factory in Pasig is transitioning to renewable energy sources, with solar panels installed on-site to generate clean electricity. These efforts align with Mitsubishi’s global sustainability goals, including its target of achieving carbon neutrality by 2050.

Future Plans for Electric Vehicles

As part of its sustainability strategy, Mitsubishi is preparing to introduce assembly lines for electric and hybrid vehicles at the Pasig factory. This initiative represents a significant step toward reducing the environmental impact of transportation while meeting the growing demand for eco-friendly vehicles.

Community Engagement

Educational Programs

The Mitsubishi Factory in Pasig is committed to educating the public about automotive manufacturing and sustainability. Through partnerships with schools and universities, the factory hosts educational tours and workshops that provide students with valuable insights into modern manufacturing processes.

Corporate Social Responsibility

Mitsubishi actively supports community development through various corporate social responsibility (CSR) initiatives. These include:

- Tree-Planting Drives: Promoting reforestation to combat climate change.

- Supporting Communities: Impacted by Natural Disasters Through Relief Efforts.

- Scholarship Programs: Offering financial assistance to underprivileged students pursuing education in engineering and technical fields.

These activities reflect Mitsubishi’s dedication to creating a positive impact beyond its business operations.

Challenges and Future Prospects

Adapting to Industry Trends

The automotive industry is undergoing a major transformation, driven by advancements in electric vehicles (EVs), autonomous driving, and connected technologies. The Mitsubishi Factory in Pasig must adapt to these changes while addressing the unique needs of the Philippine market.

- Electric Vehicle Transition

- Establishing EV assembly lines requires significant investment in new machinery and infrastructure.

- Mitsubishi must also collaborate with local suppliers to develop EV components, such as batteries and charging systems.

- Meeting Consumer Expectations

- Filipino consumers demand vehicles that offer a balance of affordability, performance, and sustainability.

- Mitsubishi must innovate to meet these expectations while maintaining competitive pricing.

Expansion Plans

To secure its position as a leader in the Philippine automotive industry, Mitsubishi has outlined ambitious expansion plans for the Pasig factory. These include:

- Increasing production capacity to meet growing demand.

- Enhancing digitalization and automation in manufacturing processes.

- Collaborating with local research institutions to foster innovation in vehicle design and production.

FAQs

1. What products are manufactured at the Mitsubishi Factory in Pasig?

The factory produces popular Mitsubishi vehicles such as the Mirage, L300, and Montero Sport. It also manufactures parts and components for export, contributing to Mitsubishi’s global supply chain.

2. How does the factory contribute to the local economy?

The factory provides thousands of jobs, supports local suppliers, and reduces reliance on imported vehicles, boosting the Philippines’ industrial sector.

3. What sustainability practices are in place at the factory?

The factory incorporates energy-efficient systems, waste recycling programs, and renewable energy sources like solar panels. It also conserves water through advanced recycling technologies.

4. Can the public visit the Mitsubishi Factory in Pasig?

The factory occasionally hosts educational tours for students and professionals. These visits are usually pre-arranged and focus on showcasing modern manufacturing processes.

5. What are the factory’s future plans?

Mitsubishi aims to expand the factory’s capabilities to include electric vehicle production, enhance automation, and foster innovation through partnerships with local institutions.

Conclusion

The Mitsubishi Factory in Pasig is a shining example of industrial excellence in the Philippines. From its innovative manufacturing practices and sustainability initiatives to its significant economic contributions, the factory underscores Mitsubishi’s commitment to quality and progress.

As the automotive industry continues to evolve, the Pasig facility remains a critical player in Mitsubishi’s global operations. By embracing innovation, fostering community engagement, and driving economic growth, the Mitsubishi Factory in Pasig solidifies its reputation as a leader in the automotive sector and a key contributor to the Philippines’ industrial future.